Vacuum Interstice Monitoring Sensor for tanks' and pipes' leak monitoring.

A compact, space-saving sensor technology for mounting in the manhole and with a separate indicating unit for indoor installation. Integrated in the sensor: a pressure sensor, a solenoid valve, a capacitive sensor for both the detection of liquid and differentiation in water and product.

Separate pump units for tanks and/or pipes are controlled by the sensor via the indicating unit.

The coloured 5.7" touch screen allows a quick registration of the system's status and a convenient entry.

TYPES:

VIMS 34 Tank: for tanks with a suction line to the low point of the interstitial space

VIMS 320 Tank: for tanks with a diameter of up to 2.9 meters without a suction line to the low point of the interstitial space

VIMS 230 Pipe: for pressure systems

VIMS 500 Pipe: for suction systems

TANKS/PIPES:

- Underground double-walled tanks/pipes

- Maximum feed pressure in the inner pipe: <= 6 bar

- Underpressure resistance of the interstitial spaces:

VIMS 34: minimum -300 mbar

VIMS 230, 320, 350: minimum -600 mbar

VMS 500: minimum -750 mbar

STORED PRODUCTS:

Monitorable liquids: heating oil, diesel, petrol, E-85.

The VIMS sensors are also suitable for the above mentioned fuels with biogenic components – provided that they were available on the market before January 1, 2012.

The following restriction must be taken into account: Gasoline Test Fuel, RSG E 10 (Haltermann Products – Hamburg plant) was used as the test liquid, i.e. this test liquid with its chemical and physical characteristics must be representative for the fuel.

The (possible) explosive vapor-air mixtures must be classifiable into gas group II A to II B3 as well as in the temperature code T1 to T4.

INSTALLATION:

Sensor (device category 2): zone 1, preferably outdoors, in manhole

Indicating unit: indoors

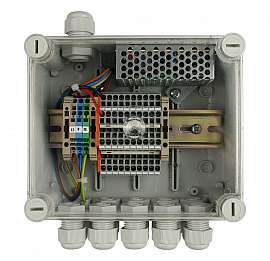

HOUSING:

Sensor: stainless steel

Indicating unit: steel coated

TEMPERATURE RANGE:

Sensor: -20 °C .. +60 °C

PRESSURE RESISTANCE:

10 bar

PNEUMATIC CONNECTIONS:

QU8/6: quick union for polyamid hose 8/6x1mm (for tanks with up to 500 mbar overpressure)

The requirements of the respective documentation must be observed!