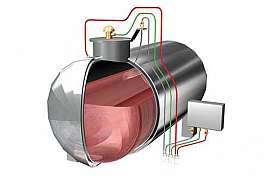

SGB leak detectors realize the highest environmental protection according to EN 13160 (class I) for double-walled tanks:

• Both the inner and the outer wall are monitored 100 % continuously and reliably for leaks.

• A loss of the stored product is excluded due to the pneumatic monitoring principle.

Our wide range of products offers the technically safe and at the same time most reasonable solution for your application.

Pressure leak detectors (DL, DLG, LDU22)

are low-maintenance and cost-effective for the monitoring of explosive as well as chemically aggressive liquids. Examples: petrol, kerosene, acid, lye

Their use requires a sufficiently overpressure resistant interstitial space of the tank.

Ex pressure leak detectors (DLG .. Ex)

If installation in an Ex zone is mandatory, then this pressure leak detector variant is optimal for monitoring containers for the storage of liquids that form explosive vapour-air mixtures or have chemically aggressive properties. Available on request.

in the simple version are maintenance-free and particularly suitable for the monitoring of heating oil and diesel

or similar non-explosive liquids. In a durable version, they are also suitable for many chemicals.

Ex vacuum leak detectors (VLX)

have explosion protection measures and can be used in different resistant designs on tanks whose interstitial spaces are not suitable for overpressure and in which explosive and/or chemically aggressive liquids are stored.