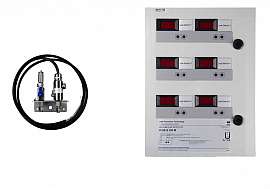

The leak detection system without its own pressure generator (static) for the monitoring of double-walled tanks with a suction line for the leak detector to the low point of the interstitial space.

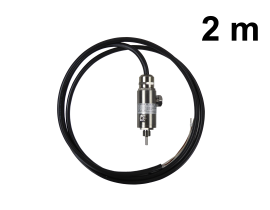

This leak detection system consists of 1 leak indicating unit and up to 6 explosion-proof sensors which are connected to the interstitial spaces pneumatically.

The interstitial space is evacuated once with an external pump to an underpressure of approx. 700 mbar. The leak detector monitors continuously the pressure in the system. The manometer (digital display) shows the current pressure.

TYPES:

VLXE-S 350 M

TANKS:

- With a suction line to the low point of the interstitial space

- Maximum diameter: 3 meters or double-walled bottom of a flat bottom tank

- Underpressure resistance of interstitial space: up to -800 mbar

STORED PRODUCTS:

Water-polluting liquids. The (possible) explosive vapor-air mixtures (also such ones that can arise through the stored/conveyed liquids in contact with air, humidity, condensation or the materials used) must be classifiable into gas group II A to II B as well as in the temperature code T1 to T4. Examples: petrol, diesel, AdBlue.

INSTALLATION:

Sensors (device category 1): at the tank in zone 1

Leak indicating unit: for wall mounting indoors, outside Ex areas

HOUSING / IP RATE / TEMPERATURE RANGE:

Sensor: stainless steel / IP 65 / -20 °C .. +60 °C

The sensor cable can be extended to a total length of 500 m using a shielded cable (e.g. article 380610) and Ex “e” junction boxes (e.g. article 220482).

Leak indicating unit: plastic box / IP 30 / -0 °C .. +40 °C

PNEUMATIC CONNECTIONS:

ss-QU8/6: stainless steel quick union for polyamide (PA) hose 8/6x1mm

ss-CF8/6: stainless steel compression ferrule for stainless steel (ss) pipe 8/6x1mm or polyamide (PA) hose 8/6x1mm

The requirements of the respective documentation must be observed!