FOR MONITORING TANKS:

For tanks at filling stations, pressure leak detectors offer the optimal benefit-cost ratio.

Several underground tanks are monitored cheaply and safely with one leak detector:

Tanks with a test pressure of the interstitial space >= 500 mbar

Tanks with a test pressure of the interstitial space >= 400 mbar

DL 280 for underground tanks with Ø ≤ 2.5 m

DL 325 for underground tanks with Ø ≤ 3.0 m

LDU22 T 280 for underground tanks with Ø ≤ 2.5 m

Pressure leak monitoring may be impossible for technical reasons, e.g. if the test pressure in the interstitial space is too low or if the system has been changed over from liquid leak detection. In this case, monitoring of the tanks with explosion-proof vacuum leak detectors is an alternative:

VLXE 34 M for steel tanks with leak protection lining and suction line to the low point of the interstitial space, in which carburetor fuels such as gasoline are stored

FOR MONITORING PIPES:

At filling stations with a pressure system (submersible pump in the tank), pipes are monitored with an explosion-proof vacuum leak detector:

VLX(E) 330 A-Ex

At filling stations with a suction system (pump is in the fuel dispenser), pipes are monitored with an explosion-proof vacuum leak detector with at least 500 mbar alarm underpressure.

Alternatively, the following pressure leak detectors can be used for pipes:

DLR-P 2.0 for filling/suction/gas recirculation pipes

DLR-P 4.5 for filling/suction/gas recirculation pipes and pressure pipes to satelites with maximum 3.5 bar feed pressure

DLR-P .. CV for plastic pipes as filling/suction/gas recirculation pipes

LDU22 P 1.1 oder LDU22 P3.5 for suction pipes or pressure pipes up to 2.5 bar

DLR-G .. M nitrogen based ; re-filling is from a stationary connected nitrogen bottle

DLR-GS .. N nitrogen based; static, without connected nitrogen bottle

COMBINED SOLUTIONS FOR MONITORING TANKS AND PIPES:

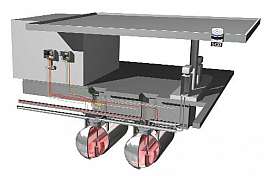

Tanks and/or pipes at filling stations can be monitored with the cost-saving outdoor solutions:

LDU22 .. : monitoring based on overpressure of up to 18 tanks or up to 32 pipes or a combination of up to 28 tanks/pipes

VLXE-SAB T ../P .. : monitoring based on underpressure of up to 16 tanks and/or pipes

VIMS: monitoring based on underpressure of up to 32 tanks and pipes

SAMPLE APPLICATIONS:

Pressure leak detector – several underground double-walled tanks (monitored with air)

Vacuum leak detector – several double-walled pipes via a manifold

Pressure leak detector – several double-walled pipes (monitored with air)